- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-11-06 Origin: Site

Have you ever wondered what happens when a motor fails to start? It could be due to a faulty motor starter capacitor. This small component plays a key role in providing the necessary torque to start motors under load.

In this article, we’ll dive into the importance of testing a motor starter capacitor, how it works, and the tools required to ensure it functions properly. You'll also learn how intelligent motor control and protection can prevent motor failures by keeping capacitors in optimal condition.

Regular testing of the motor starter capacitor is essential for ensuring the motor operates smoothly and efficiently. If the capacitor malfunctions, the motor might fail to start, may hum without turning, or could overheat. Testing the capacitor can identify early signs of wear, such as a drop in capacitance or a short circuit, helping prevent further damage to the motor or other connected components. A multi-function motor starter relies heavily on the integrity of the capacitor to provide reliable motor operation.

Testing is especially important in situations where motors work under load, like in industrial applications. Over time, capacitors may degrade due to temperature, electrical surges, or general wear, leading to motor performance issues. The connection between motor control and protection switches and a functioning motor starter capacitor is clear: the capacitor ensures the motor gets the necessary initial torque to avoid damage or failure during startup.

The role of the motor starter capacitor is to provide an initial energy boost to the motor, allowing it to start efficiently. Without it, the motor would struggle to overcome the inertia and load, leading to stalling or failure to start. The capacitor’s health directly affects the motor’s efficiency—well-maintained capacitors ensure smoother startups and prevent unnecessary strain on the motor. In more advanced intelligent motor control and protection systems, the capacitor helps the motor perform optimally by ensuring a consistent phase shift.

To test a motor starter capacitor, you need a digital multimeter that is capable of measuring capacitance. Some multimeters have a specific setting for testing capacitors, allowing you to easily measure the capacitor’s ability to store energy. Capacitor testers are also available, which can provide more detailed testing results, especially when dealing with large capacitors.

Additionally, you’ll need basic safety equipment such as insulated gloves and tools to ensure protection from electrical shocks when handling capacitors.

Before testing any capacitor, it’s crucial to discharge it completely to avoid electrical shock. A charged capacitor can hold a significant amount of energy, even after power is disconnected. Always ensure that the capacitor is discharged using a resistor or screwdriver with an insulated handle before starting your testing process. This step helps protect both you and your equipment.

Yes, you can use a regular multimeter to test the capacitance of a motor starter capacitor. However, to get accurate results, ensure that your multimeter has a capacitance setting. A digital multimeter is typically preferred for testing motor starter capacitors, as it provides precise readings of the capacitance value and allows you to compare it with the manufacturer’s specifications.

Before testing, you must ensure the motor is disconnected from power. Unplug the motor and let it cool down if it has been operating. Once disconnected, remove the capacitor from the motor starter by using an insulated screwdriver to unscrew it. It's crucial to ensure that the capacitor is not holding any residual charge. Use a short circuit or a discharge tool to safely drain any stored energy.

Once the capacitor is safely discharged, set your multimeter to the capacitance setting. Attach the multimeter probes to the positive and negative terminals of the capacitor. The multimeter should display the capacitance value. Compare this reading to the capacitance rating printed on the side of the capacitor. If the value is within the acceptable range, the capacitor is functional. If not, it may need replacement.

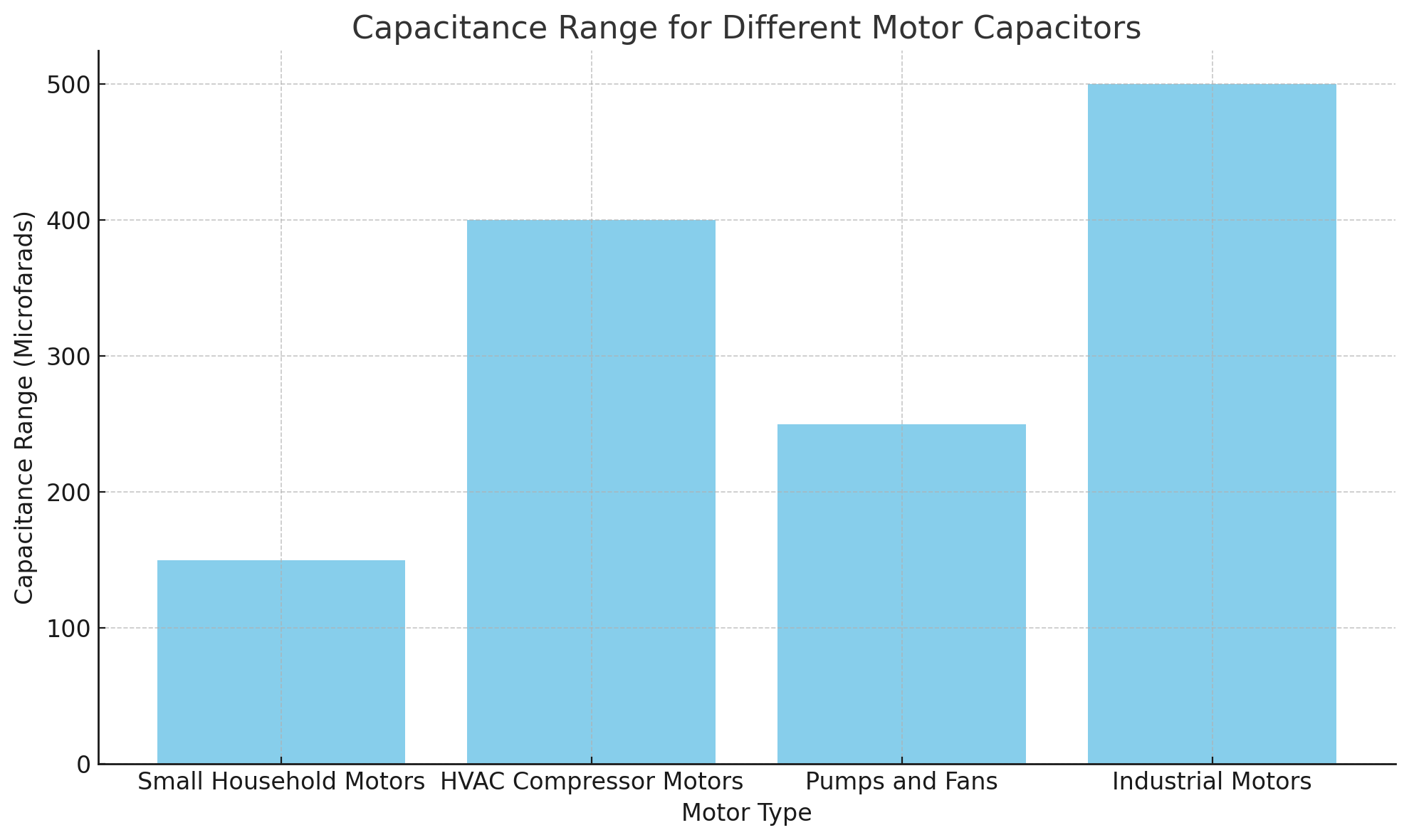

The reading you should expect depends on the capacitor’s rating. For a standard motor starter capacitor, the capacitance will generally range from 70 to 400 microfarads. If the multimeter reading is significantly lower or higher than the specified value, it indicates the capacitor is faulty. If the capacitor reads "open" or shows no fluctuation in capacitance, it is no longer operational and must be replaced.

Motor Type | Capacitance Range (Microfarads) |

Small Household Motors | 70 - 150 µF |

HVAC Compressor Motors | 100 - 400 µF |

Pumps and Fans | 80 - 250 µF |

Industrial Motors | 150 - 500 µF |

A faulty motor starter capacitor often shows visible signs of damage, such as:

● Swelling: The casing may swell due to internal pressure from the capacitor failing.

● Discoloration: The capacitor may change color, usually becoming darker or showing burn marks due to overheating.

● Leakage: If the capacitor has leaked electrolyte, this is a clear sign it needs replacing.

A malfunctioning capacitor will directly affect motor performance. Some common electrical symptoms include:

● Motor Humming Without Turning: The motor attempts to start but cannot turn over.

● Failure to Start: If the motor fails to start altogether, a faulty capacitor could be the cause.

● Overloaded Motor: The motor may trip the overload protection circuit frequently due to poor performance.

If your capacitor shows signs of failure or the test results indicate it’s not functioning properly, replace it immediately. You can find compatible replacements at electrical supply stores, ensuring that the replacement matches the specifications of the original capacitor.

Replacing a faulty motor starter capacitor is straightforward, but safety is key. First, ensure the power is off and the motor is completely disconnected from the electrical supply. After discharging the faulty capacitor, carefully remove it and replace it with a new one of the same capacitance rating. Secure the new capacitor and reconnect the wires.

If you're unsure about handling electrical components, or if the capacitor is difficult to access, it’s always a good idea to consult a professional. A licensed electrician or technician can help ensure the capacitor is properly replaced and the motor starter is functioning optimally.

To extend the life of your motor starter capacitor, it’s essential to regularly inspect it for any signs of wear or damage. Avoid exposing the capacitor to extreme temperatures or electrical spikes. Intelligent motor control and protection systems can help reduce stress on the capacitor by managing power fluctuations and ensuring the motor operates within safe limits.

Symptom | Cause |

Motor Hums but Doesn't Start | Capacitor not providing enough torque |

Motor Starts and Stalls | Capacitor losing capacitance |

Capacitor Case Swelling/Discoloration | Capacitor overheating or failure |

Blown Fuse or Tripped Breaker | Short-circuit or capacitor failure |

● Check the capacitor periodically for signs of bulging, leakage, or discoloration.

● Ensure proper ventilation around the motor and capacitor to prevent overheating.

● Use surge protectors to protect the motor and capacitor from electrical surges.

Testing your motor starter capacitor regularly is essential for ensuring smooth motor operation and preventing costly repairs. Understanding how to test the capacitor using a multimeter helps identify potential issues early. By choosing multi-function motor starters with built-in motor control and protection switches, like those from Radin Electric, you can improve system efficiency and extend motor lifespan. Regular maintenance will safeguard your equipment, ensuring reliable performance and fewer breakdowns.

A: A motor starter capacitor provides the extra torque needed for single-phase motors to start under load, improving motor efficiency and performance.

A: To test a motor starter capacitor, use a multimeter set to capacitance mode. Compare the reading with the capacitor’s rated value to check if it’s functioning properly.

A: Testing ensures the motor starter capacitor functions correctly, preventing motor failure, stalling, or humming, and improving efficiency in multi-function motor starters.

A: Yes, a digital multimeter with a capacitance setting can test the motor starter capacitor. Ensure the capacitor is discharged before testing to avoid damage.

A: If the motor starter capacitor is faulty, replace it with a new one of the same specifications to ensure reliable motor startup and protect the motor control and protection switch.