- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Have you ever wondered how motors start smoothly without causing damage? A motor starter is the key to ensuring this safe and efficient operation. These devices not only start and stop motors but also provide essential protection against issues like overloads and overheating.

In this article, you will learn about the key components of a multi-function motor starter, how it works, and the importance of intelligent motor control and protection in optimizing performance. By the end, you'll know how to choose the right motor control and protection switch for your needs.

A motor starter is an electrical device used to manage the flow of electricity to a motor, controlling its startup, stopping, and providing protection from electrical faults. These devices are vital in industrial and commercial applications, ensuring that motors operate safely and efficiently without causing damage from excessive current or overheating.

Motor starters are equipped with contactors and overload relays, which allow them to control the power supply and protect the motor from adverse conditions. Whether it's a small machine or large industrial equipment, motor starters are crucial to prolong the life of motors and reduce maintenance costs.

The contactor is a critical component in any motor starter system. Its primary function is to open and close the electrical circuit that powers the motor. When the motor needs to be started, the contactor closes the circuit, allowing electrical current to flow to the motor. In contrast, when the motor needs to be stopped, the contactor opens the circuit, halting the current flow.

This process is controlled by an electromagnetic field created by the contactor coil, which is energized when a signal is received from the control circuit. This ensures that the motor is started and stopped safely, with precise control over the power supply.

An overload relay is a protective device that safeguards the motor from overheating caused by excessive current. When the motor draws more current than it is rated for, the overload relay detects this condition and disconnects the power to the motor, preventing damage.

Overload protection is essential for preventing motor burnout and ensuring that the motor operates within its safe limits. Some motor starters also feature adjustable settings for overload relays, which can be tailored to the motor's specifications.

Motor starters consist of two main circuits: the power circuit and the control circuit.

● Power Circuit: The power circuit handles the flow of electricity to the motor. This is where the contactor makes or breaks the current flow, directing the electrical supply to the motor through the starter's contacts.

● Control Circuit: The control circuit is responsible for energizing the contactor coil and activating the starter's functions. This circuit is usually connected to pilot devices such as buttons, sensors, and switches that allow for manual or automated control of the motor.

Understanding how these circuits work together ensures that the motor is safely powered on or off when needed.

The operation of a motor starter is relatively straightforward. Upon receiving a signal from the control circuit (like pressing a start button), the contactor closes, allowing electrical current to flow to the motor. The overload relay simultaneously monitors the motor's current and will disconnect the power if the motor draws excessive current.

This process allows for safe and efficient motor operation, preventing damage from high starting currents and ensuring that the motor operates within safe temperature limits.

There are various methods used to start motors, depending on the motor size, application, and desired performance:

● Direct-On-Line (DOL) Starter: This is the simplest method, where the motor is directly connected to the power supply. It’s best for small motors but can cause high inrush currents.

● Star-Delta Starter: This method reduces the initial current by connecting the motor windings in a star configuration during startup, then switching to a delta configuration for normal operation.

● Variable Frequency Drive (VFD): VFDs are advanced starters that control the speed and torque of the motor by adjusting the frequency of the electrical power supplied. They offer superior energy efficiency and are ideal for applications requiring precise control.

Motor starters provide various protection mechanisms, including:

● Overload Protection: Prevents the motor from drawing excessive current, which can cause overheating and damage.

● Short-Circuit Protection: Ensures that the motor is disconnected from the power supply in the event of a short circuit.

● Voltage Protection: Protects the motor from damage due to low or high voltage conditions.

These protection features ensure that motors operate safely and efficiently, reducing the risk of failure and minimizing the need for repairs.

Manual motor starters are the most basic type. They are simple to use and do not require any electrical control circuits. The user can start or stop the motor manually by pressing a button or turning a knob. While these starters are cost-effective and easy to install, they may not provide sufficient protection against power loss or inrush currents, and they lack automation features.

Magnetic starters operate electromagnetically. They use a coil to energize and de-energize the contactor, allowing the motor to start or stop automatically. These starters are equipped with overload relays for added protection, making them suitable for a wide range of industrial applications.

Soft starters are used to gradually increase the voltage supplied to the motor during startup. This smooth acceleration minimizes mechanical stress and electrical inrush currents, reducing wear and tear on the motor and associated equipment. Soft starters are ideal for applications where reducing motor strain is critical, such as conveyors or large machinery.

VFDs are advanced motor starters that allow for precise speed control. By adjusting the frequency and voltage supplied to the motor, VFDs can optimize motor performance and energy efficiency. They are particularly useful in applications requiring variable speeds or precise torque control, such as pumps, fans, and mixers.

When selecting a motor starter, it’s important to consider factors such as:

● Motor Size: Larger motors may require more advanced starters like VFDs or soft starters to manage inrush currents and optimize performance.

● Application Type: Different applications have different demands, such as the need for precise speed control or protection against frequent starts and stops.

● Overload Protection: Ensure that the motor starter includes sufficient overload protection to safeguard the motor from excessive current and overheating.

● Small Motors (Up to 5 HP): DOL starters are usually sufficient for small motors, offering a simple and cost-effective solution.

● Medium Motors (5-100 HP): Star-Delta starters are ideal for medium-sized motors, as they reduce inrush currents and provide reliable protection.

● Large Motors (100 HP and above): Soft starters or VFDs are best suited for large motors, as they provide smooth acceleration, energy efficiency, and precise control.

Each type of motor starter has its advantages, depending on the motor’s size and application:

● DOL Starters: Simple and economical but cause high inrush currents.

● Star-Delta Starters: Reduce inrush current but have momentary power loss during switching.

● Soft Starters: Provide smooth acceleration but are more expensive than DOL starters.

● VFD Starters: Offer superior control and energy efficiency but come with higher upfront costs.

Intelligent motor control systems, such as VFDs, not only offer precise speed control but also help reduce energy consumption. By optimizing the motor’s performance based on real-time load requirements, these systems can achieve significant energy savings, making them a smart choice for industries focused on reducing operational costs.

Overload protection is critical to preventing motor damage, but it can fail if not properly maintained. Regularly testing and recalibrating the overload relay is essential to ensure proper functionality. If the motor continues to trip the overload relay, it may indicate a need for inspection and adjustment.

Common electrical faults include short circuits, poor connections, or faulty control circuits. These issues can cause the motor starter to malfunction, leading to system instability. Troubleshooting these issues involves checking wiring connections, inspecting circuit components, and testing for any electrical anomalies.

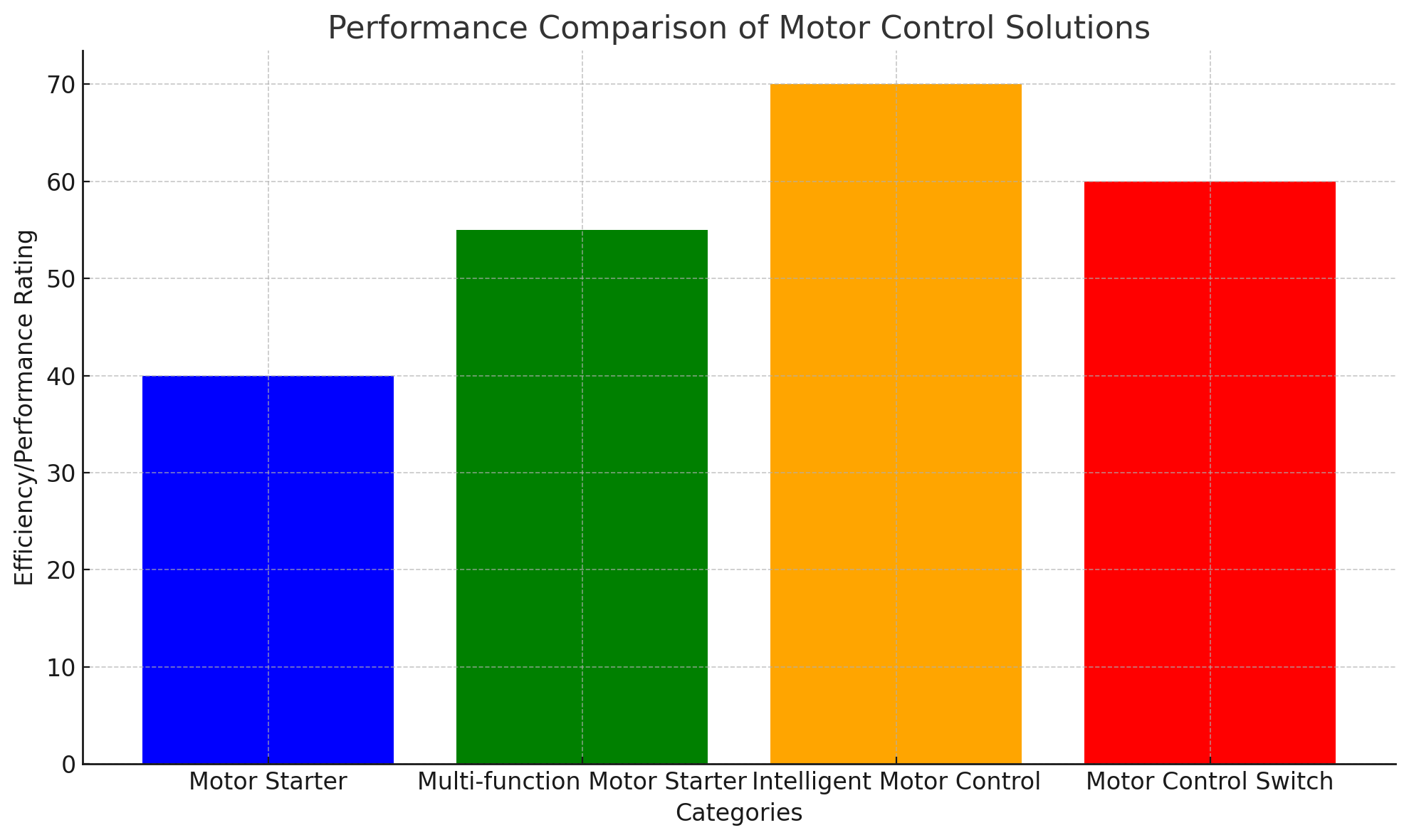

Motor starters are crucial for ensuring the safe and efficient operation of motors in industrial settings. Selecting the right starter, whether for small or large motors, helps reduce downtime, prevent damage, and improve energy efficiency. Understanding various types of starters, along with their protection features, enables informed decisions. By choosing Radin Electric products, which focus on intelligent motor control and protection, you can optimize performance and reduce long-term costs, ensuring reliable operations across industries.

A: A motor starter is an electrical device that helps safely start, stop, and protect electric motors from issues like overloads and overheating.

A: A multi-function motor starter controls the motor's power supply, offering features like overload protection and reversing, ensuring smooth and safe operation.

A: Intelligent motor control and protection optimize motor performance, reducing energy consumption and preventing damage by adjusting motor speed and power usage.

A: Choosing the correct motor control and protection switch depends on factors like motor size, application, and the level of protection required for safe operation.